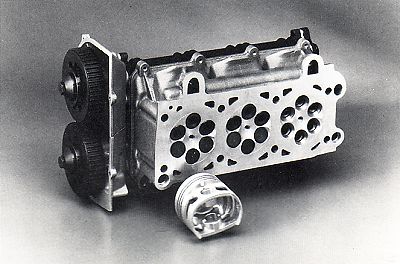

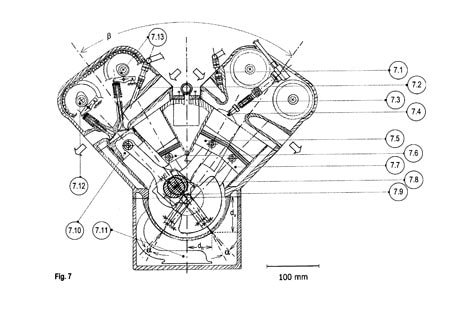

For installing to smaller and lower price cars, W8 is a logical development from the W12. However, W8 does not balance inherently, unlike W12. Like all W engines, the W8 has 5 main bearings and 4 crank throws like a conventional V8. It should have balanced as well as any conventional V8s, but space reason doesn’t allow. If you remember, conventional V8s can have 2 configurations:

1) flat-plane V8: some high performance V8s use this configuration. It works like a combination of 2 inline-4 engines so that there is quite a lot of second order vibration generated. However, these engines usually employ short stroke and lightweight pistons / con-rods to enhance power, thus vibration is also largely reduced.

2) Cross-plane V8: most V8s - including all sedans V8s - employ this configuration. It uses large counter balances incorporated in the crank throws to cancel the force generated by pistons and con-rods, thus all vibration is eliminated.

Because W8 is far shorter than conventional V8s, its crank throws are machined extremely thin and have no space for adding large counter balances. As a result, it employs the flat-plane configuration. Therefore W8 does not generate the "rumble bumble" noise like conventional V8s.

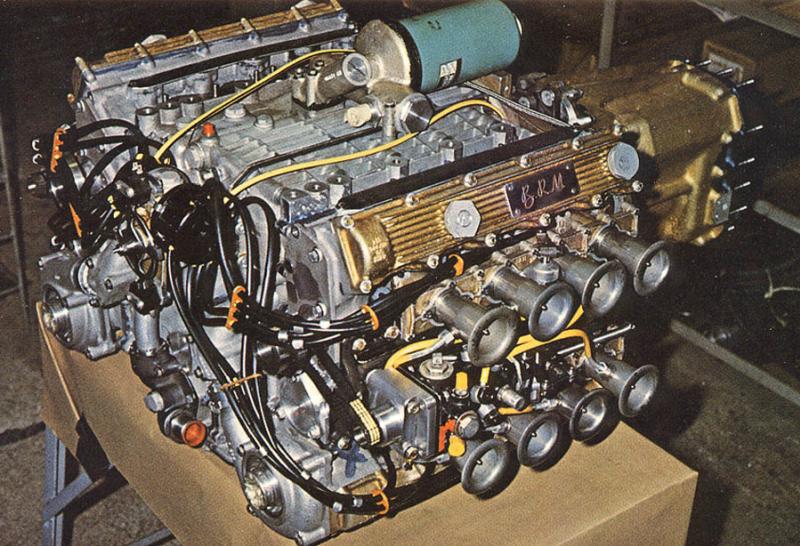

On the other hand, being a mass production sedan engine, W8 would have actually generated more vibration than the high performance V8s from Ferrari, Lotus and TVR, because:

1) Long stroke: the narrow-angle configuration does not allow bores too large, otherwise combustion chambers in adjacent banks would have been overlapped. Moreover, a sedan engine requires to generate a health amount of torque. No wonder Passat’s 4.0 W8 has a stroke measuring 90.2mm, longer than the bore of 84mm.

2) Heavier pistons: while Ferrari uses lightweight forged pistons and titanium connecting rods, the W8 can only seek more cost-effective method to cut weight from pistons.

To sports car V8s, a bit vibration means nothing. To the sedan-use W8, the only choice is to add twin-balancer shaft like many inline-4 engines.