new apprentice getting into the field looking for opnioons on beginners tool sets i have about 2-3 k to spend starting what would you experienced guys recommend i have some mac tools basics i have a 50percent discount on mac and snap on so was just wondering whats really worth getting from there I'm not gonna be a dealer guy I'm working at a corner shop that deals with all kinds a lot of euro since we got a used dealer on contract any input is appreciated thanks guys sorry for the horrendous grammar

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

just finished auto mech school looking for input on tools

- Thread starter ilikecars

- Start date

Gregster

Legacy Member

I've been in this game for what feels a lifetime already, I have seen many enthusiastic young apprentices spend money on tools only to quit the trade after the first winter either because it was too cold for them or got laid off.. My advice is use that 50% discount on Snap On Wrenches, sockets and ratchets because you'll never never a deal like that on the truck and if you don't like the trade you can always sell the tools for a little loss, Snap-On (doesn't matter the age) holds value stupid good. .. Impact gun I swear by Ingersol-Rand. Another piece of adjust invest in a 3/8 cordless impact to speed up work and most importantly save your hands from cramping up (As I said I have been doing this for ages and I wish we had 3/8 Li impacts back when I started)

Don't bother trying to get a job without the basic tools, regardless of brand. I wouldn't hire anyone without basic tools. Small things I don't mind lending out but after 2-3 times you should have bought said tool. Buy multiple 10mm wrenches and sockets, those always vanish just like flat head screw drivers.

For Euro you will also need ETorx, Torx, Allen and XZN sockets as well complete sets. Get yourself a set of those bolt extractor things for when you strip an allen, torx or xzn. 12pt axle nut sockets are valuable as well

Digital torque wrenches in 1/4 and 3/8.. Don't bother with click type. Everything is torque angle based now for example 25nm + 130 degrees

Don't bother trying to get a job without the basic tools, regardless of brand. I wouldn't hire anyone without basic tools. Small things I don't mind lending out but after 2-3 times you should have bought said tool. Buy multiple 10mm wrenches and sockets, those always vanish just like flat head screw drivers.

For Euro you will also need ETorx, Torx, Allen and XZN sockets as well complete sets. Get yourself a set of those bolt extractor things for when you strip an allen, torx or xzn. 12pt axle nut sockets are valuable as well

Digital torque wrenches in 1/4 and 3/8.. Don't bother with click type. Everything is torque angle based now for example 25nm + 130 degrees

CRNKY

New member

I would forget about the MAC tools, every single air tool I had from them broke in 2 years. IR for gun and snap-on for impact hammer, Blue Point got a nice ¼" mini air ratchet and other air tools I'm happy with so far. Picked up a Yamaha grinder/cutter because it was stupid cheap so I was like why not, still fine after 4 years.

Save money by buying snap-on sockets when they're on special with the ratchets. Or use your 50% deal now.

52"+ tool chests with bench tops and 1-2 full length top drawers are great, Costco used to have some for around 1K, kijiji is ok but don't buy anything without bearings.

Ask the snap-on guy if he got anything used for sale, mine always have stuff for a good price, even tool chests.

The snap-on guy also buys your cheap stuff so you can buy his stuff, he gets refunded.

Some stuff sold as sets for a lower price than singles are not worth it because half of it you'll never use so you saved nothing.

Anything that looks flimsy but you're thinking of buying it because it's cheap will fall apart, bend, or break.

Save money by buying snap-on sockets when they're on special with the ratchets. Or use your 50% deal now.

52"+ tool chests with bench tops and 1-2 full length top drawers are great, Costco used to have some for around 1K, kijiji is ok but don't buy anything without bearings.

Ask the snap-on guy if he got anything used for sale, mine always have stuff for a good price, even tool chests.

The snap-on guy also buys your cheap stuff so you can buy his stuff, he gets refunded.

Some stuff sold as sets for a lower price than singles are not worth it because half of it you'll never use so you saved nothing.

Anything that looks flimsy but you're thinking of buying it because it's cheap will fall apart, bend, or break.

SUBARU_WRX_STi

Well-known member

snap on air tools are amaizing,IR is very good too,but less powerfull than snap on.

There was a guy at work was using a 3/4 inch drive IR gun tu remove a 1 1/8 bolt, it didnt move, i used my 1/2 drive snap on gun, removed it right away

Sent from my SM-N910W8 using Tapatalk

There was a guy at work was using a 3/4 inch drive IR gun tu remove a 1 1/8 bolt, it didnt move, i used my 1/2 drive snap on gun, removed it right away

Sent from my SM-N910W8 using Tapatalk

newschooler

Legacy Member

I've been in this game for what feels a lifetime already, I have seen many enthusiastic young apprentices spend money on tools only to quit the trade after the first winter either because it was too cold for them or got laid off.. My advice is use that 50% discount on Snap On Wrenches, sockets and ratchets because you'll never never a deal like that on the truck and if you don't like the trade you can always sell the tools for a little loss, Snap-On (doesn't matter the age) holds value stupid good. .. Impact gun I swear by Ingersol-Rand. Another piece of adjust invest in a 3/8 cordless impact to speed up work and most importantly save your hands from cramping up (As I said I have been doing this for ages and I wish we had 3/8 Li impacts back when I started)

Don't bother trying to get a job without the basic tools, regardless of brand. I wouldn't hire anyone without basic tools. Small things I don't mind lending out but after 2-3 times you should have bought said tool. Buy multiple 10mm wrenches and sockets, those always vanish just like flat head screw drivers.

For Euro you will also need ETorx, Torx, Allen and XZN sockets as well complete sets. Get yourself a set of those bolt extractor things for when you strip an allen, torx or xzn. 12pt axle nut sockets are valuable as well

Digital torque wrenches in 1/4 and 3/8.. Don't bother with click type. Everything is torque angle based now for example 25nm + 130 degrees

Click type are that shitty?

I also don't understand the angle thing. You turn clockwise to screw and thats it? lol

CRNKY

New member

snap on air tools are amaizing,IR is very good too,but less powerfull than snap on.

There was a guy at work was using a 3/4 inch drive IR gun tu remove a 1 1/8 bolt, it didnt move, i used my 1/2 drive snap on gun, removed it right away

Sent from my SM-N910W8 using Tapatalk

Power always depends which model you buy, there are some strong IR guns. I use this on everything big like trucks

SUBARU_WRX_STi

Well-known member

Yeah but you dont always have space lolPower always depends which model you buy, there are some strong IR guns. I use this on everything big like trucks

https://images-na.ssl-images-amazon.com/images/I/71BN39XkAsL._SX522_.jpg

Sent from my SM-N910W8 using Tapatalk

Gregster

Legacy Member

Click type are that shitty?

I also don't understand the angle thing. You turn clockwise to screw and thats it? lol

I haven't used a click type in years unless it's been for torquing wheels...

CRNKY

New member

best price ever for magnetic trays

-Phil-

Active member

Click type are that shitty?

I also don't understand the angle thing. You turn clockwise to screw and thats it? lol

"finger tight"+angle. Selon le thread pitch pi l'élongation sous stress de la bolt/nut que tu torque, X° d'angle va donner Y lbs-ft de torque.

Quand tu torque avec une mesure de torque, la friction de la bolt/nut sur la surface qui est bolté va affecté le clamping force. Une surface plus "rough" va mettre plus de drag sur la bolt/nut donc une partie du torque appliqué pour serrer la bolt/nut va etre utilisé juste pour combattre la friction sur la surface.

Avec l'angle, le clampng force est pas affecté par les surfaces des pieces. T'as un torque plus constant.

http://www.assemblymag.com/articles/87404-fastening-threads-torque-control-vs-angle-control

Gregster

Legacy Member

-Mike-

Premium

Les torque wrench a click le gros probleme est que le monde savent pas s'en servir.

Quand j'étais au centre de recherche de BRP on avait un tite madame de Qualité Sur qui calibrait nos outils régulierement (load cell, torque wrench, gauge de pression, etc) et les torques wrench a clic était tres accurate.

Pour le ''angle thing'' ca fait 10 ans j'en parle et le monde me prenait pour un extra terrestre..... Le gros probleme est surtout la lubrification. Le clamping force d'un ensemble vis et écrou qui a été torqué a 30lbs pied avec de l'huile sur les filets sera beaucoup plus élevé que le clamping force du meme ensemble serrer a sec.

J'ai faite des séries de test la dessus chez BRP, y'a des cas que ca prenait 2x plus de force pour stripper la vis a sec VS lubrifier. Ca peut donc énormément influencé le couple réel de serrage.

Encore la, faut que le gars sache travaillé pcq si ton premier ''torque'' a été mal fait, ton 1/3 de tour vaudra rien.

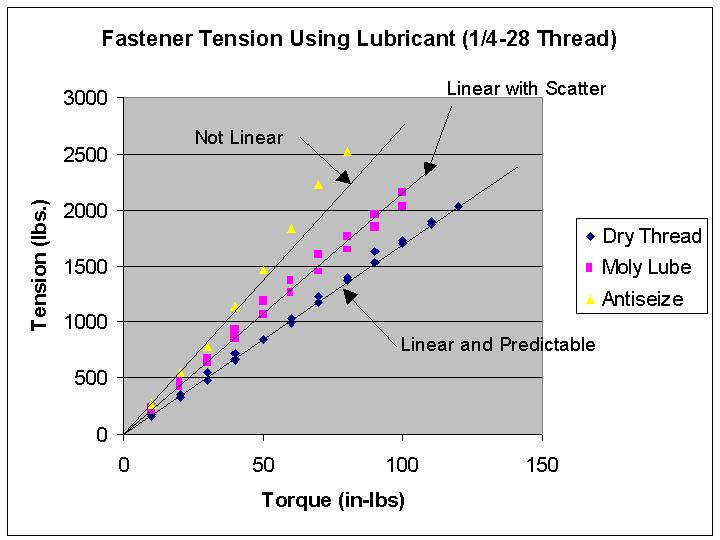

Un graphique indicant la force de serrage d'un ensemble en fonction du torque appliqué, avec ou sans lub on voit la différence

Pour

Quand j'étais au centre de recherche de BRP on avait un tite madame de Qualité Sur qui calibrait nos outils régulierement (load cell, torque wrench, gauge de pression, etc) et les torques wrench a clic était tres accurate.

Pour le ''angle thing'' ca fait 10 ans j'en parle et le monde me prenait pour un extra terrestre..... Le gros probleme est surtout la lubrification. Le clamping force d'un ensemble vis et écrou qui a été torqué a 30lbs pied avec de l'huile sur les filets sera beaucoup plus élevé que le clamping force du meme ensemble serrer a sec.

J'ai faite des séries de test la dessus chez BRP, y'a des cas que ca prenait 2x plus de force pour stripper la vis a sec VS lubrifier. Ca peut donc énormément influencé le couple réel de serrage.

Encore la, faut que le gars sache travaillé pcq si ton premier ''torque'' a été mal fait, ton 1/3 de tour vaudra rien.

Un graphique indicant la force de serrage d'un ensemble en fonction du torque appliqué, avec ou sans lub on voit la différence

Pour

Get yourself snap on ratchet and flank drive wrenches. Air tools any ir is a good deal. Impact wis i have an ir titanium and for heavy work i got myself an air cat which is a realy good bang for the buck( about 330). I would not go for snap on sockets to start with unless you work alot with torx, triple square etc.. Everything electric power tools with snap is amazing from my point of view. Screwdriver no brainer go with snap on you wont regret. Not a big fan of mac since you can find the same exact tools from other brand at half the price. 1/2 impact swivel socket is pretty expensive but definetly worth every penny.

newschooler

Legacy Member

"finger tight"+angle. Selon le thread pitch pi l'élongation sous stress de la bolt/nut que tu torque, X° d'angle va donner Y lbs-ft de torque.

Quand tu torque avec une mesure de torque, la friction de la bolt/nut sur la surface qui est bolté va affecté le clamping force. Une surface plus "rough" va mettre plus de drag sur la bolt/nut donc une partie du torque appliqué pour serrer la bolt/nut va etre utilisé juste pour combattre la friction sur la surface.

Avec l'angle, le clampng force est pas affecté par les surfaces des pieces. T'as un torque plus constant.

http://www.assemblymag.com/articles/87404-fastening-threads-torque-control-vs-angle-control

Ok donc, dans l'exemple a gregster, comment tu torque a 25nm a 130 degree? Si tu me décrit l'action, p-e que je vais comprendre plus. Parceque pour le moment, je comprend pas comment un torque wrench électronique est capable de détecter le coéficient de friction ( a moin qu'il le soit?????)

CRNKY

New member

Frank, Air Cat and MAC are manufactured by the same company. I used AC parts ordered online to fix my broken MAC after I found out that they are identical. What a rip off

the MAC truck doesn't come around for years now to have him replace all the junk I have from them broken lol

the MAC truck doesn't come around for years now to have him replace all the junk I have from them broken lol